Class 1 Ceramic Dielectrics

- Posted by doEEEt Media Group

- On July 28, 2020

- 0

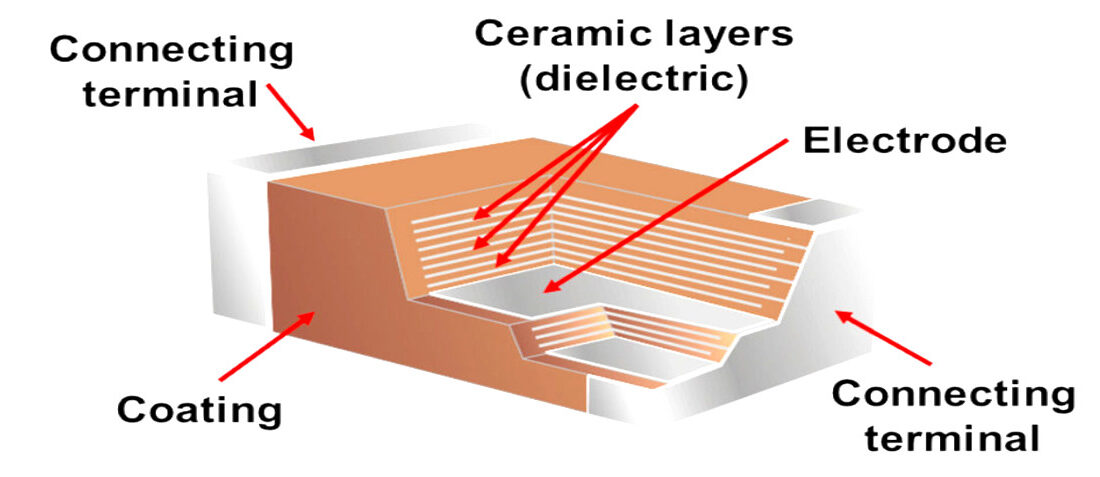

Ceramic capacitors are some of the most widely used passive components in today’s analog and digital electronic circuits. The performance characteristics of these passive components are greatly determined by the dielectric material used.

Some of the most commonly used ceramic dielectric materials include C0G (NP0), U2J, X7R, X5R, Z5U, and Y5V. Ceramic dielectrics are broadly classified into Class I, Class II, and Class III dielectrics. C0G is the most common Class I dielectric material, while X7R, Z5U and Y5V are the most common Class II type dielectrics. Class III dielectrics are rarely used today.

Characteristics of Class 1 ceramic dielectrics

Class 1 dielectrics are ultra-stable; variations in frequency, temperature, or voltage over time have minimal effects on the performance characteristics of Class 1 capacitors.

The Electronic Industries Alliance (EIA) classifies ceramic dielectrics into different categories depending on their dielectric constant, also known as relative permittivity (ϵr). This property of a dielectric material determines the amount of energy that a capacitor can store compared to vacuum. A class of ceramic dielectrics is further divided into sub-classes depending on the temperature characteristics of the materials. Some of the most common Class 1 dielectrics include C0G and U2J.

C0G, also commonly known as NP0, is an ultra-stable dielectric material. This ceramic dielectric material has low relative permittivity. Due to its low permittivity, C0G ceramic capacitors have low capacitance. Manufacturers use different formulations to produce C0G, since the EIA classification does not define the material. Most C0G dielectrics are made of non-ferroelectric materials. The response of these materials to temperature and voltage is linear. Moreover, Class I dielectrics do not exhibit microphonic characteristics and have low dielectric loss.

Advancements in C0G formulations have helped to improve the performance characteristics of C0G ceramic capacitors. Traditionally, C0G dielectric materials use barium neodymium titanate (BNT). These dielectric materials are compatible with Precious Metal Electrodes (PME) such as silver-palladium (AgPg) alloy. To enhance the performance characteristics of ceramic capacitors, most manufacturers have switched to Base Metal Electrode (BME) C0G dielectrics. These dielectrics are mainly based on calcium zirconate (CaZrO3). Calcium zirconate has a lower dielectric constant than BNT. To obtain high reliability and high insulation resistance, thin layers of calcium zirconate are used. BME C0G capacitors offer higher capacitance compared to PME C0G components of same voltage rating and same physical size.

MLCC capacitor construction, credit: TDK

U2J dielectrics have higher capacitance levels than NP0. This characteristic makes U2J a suitable choice for applications that demand high capacitance levels and stable performance. Furthermore, U2J offers superior temperature performance to most Class II dielectrics.

The capacitance and dissipation factor of a ceramic capacitor are dependent on frequency. For C0G-type capacitors, changes in capacitance and dissipation factor with frequency are minimal. In comparison, variations in frequency cause significant changes in the characteristics of X7R and Z5U dielectrics. The capacitive reactance and inductive reactance of a capacitor are dependent on frequency. An increase in frequency causes an increase in inductive reactance and a decrease in capacitive reactance.

Variations in temperature affect capacitance and dissipation factor of ceramic capacitors. This change varies from one dielectric material to another depending on the formulation. Class I dielectrics have a linear temperature coefficient of capacitance (TCC). The temperature coefficient of C0G is 0 ± 30 ppm/°C for the temperature range of -55ºC to +125ºC while that of U2J is -750±120ppm/°C for the same temperature range. In addition, Class I capacitors have high insulation resistance. The insulation resistance of C0G is 106 MΩ at 25°C and 105 MΩ at 125°C.

Capacitance vs temperature chart, credit: TDK

The capacitance and dissipation factor of some ceramic capacitors are significantly affected by variations in applied voltage. The amount of capacitance loss varies depending on the formulation of the dielectric. Class 1 ceramic capacitors have superior voltage stability and most C0G formulations do not exhibit DC bias. In comparison, Class 2 and 3 dielectrics are made of ferroelectric materials, and they are significantly affected by variations in applied voltage. Just like NP0, U2J ceramic dielectrics offer excellent voltage stability. At the rated voltage, these capacitors can retain over 99% of their nominal capacitance.

Capacitor aging is a gradual process that causes a decline in the capacitance of a component with time. For some ceramic dielectric materials, a drop in temperature below the Curie temperature causes realignment in the material’s crystalline structure. This change results in a gradual loss of capacitance. Class I dielectrics do not lose capacitance with time, and C0G has an aging rate of 0% per decade hour. The aging rate of U2J is 0.1% per decade hour. In comparison, Class II and III dielectrics are highly susceptible to aging. This gradual loss in capacitance is logarithmic with time.

Applications of Class 1 ceramic dielectrics

Class 1 capacitors are mostly used in applications that demand stable performance, low acoustic noise, and low dielectric loss. C0G is used in the designing of capacitors for use in filter circuits and high-frequency circuits. U2J dielectric technology is used in the manufacturing of capacitors for use in DC blocking, tuning, transient voltage suppression, energy storage, critical timing, decoupling, data acquisition filters, PLL low pass filter, and bypassing. Although temperature compensating capacitors offer superior stability, they have low volumetric efficiency.

doEEEt provides you the most complete and updated information about Hi-Rel EEE parts

source: Capacitor Faks blog

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

- Filtering Characteristics of Parallel-Connected Fixed Capacitors in LCC-HVDC - November 21, 2024

- ALTER SPACE TEST CENTER: testing approaches for New Space - September 30, 2024

0 comments on Class 1 Ceramic Dielectrics