Constructional Analysis in Microsection Inspection

- Posted by Mari Carmen López

- On July 23, 2019

- 0

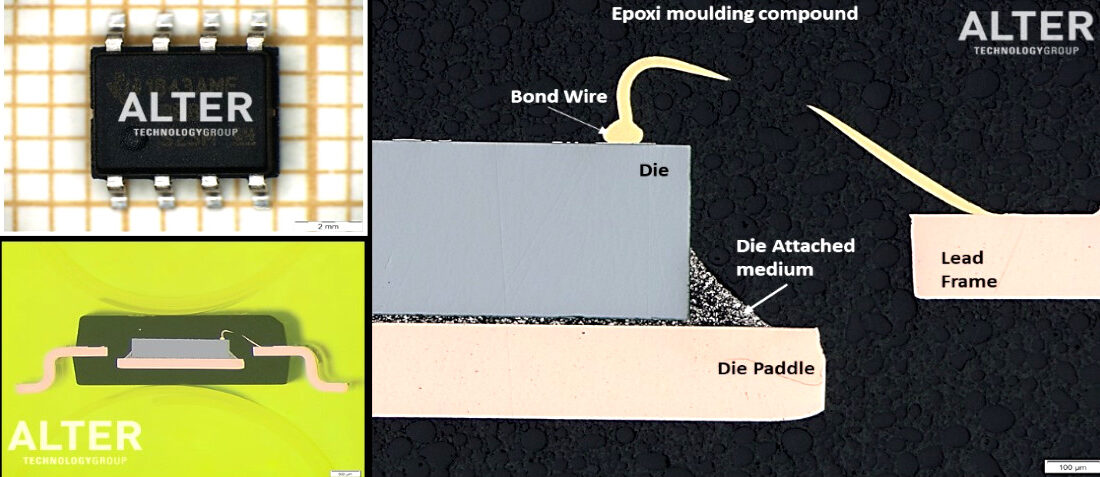

8 lead Flat Pack device (FP8) is metallographic prepared in ALTER materials & processes laboratory, recognized as a recommended facility for such activity by ESA authority (MEMO ESA-TECMSP-MO-013165).

Sample & Method

Cross-section analysis is a very useful way of determining the construction and material composition of electronic devices.

The FP device is potted in epoxy resin. After curing, the sample is sequentially grinded up to reach the plane of interest. Then, the specimen is subjected to several polishing steps to achieve a high-quality surface to be analyzed by a metallographic microscopy.

Remark

An in-depth constructional analysis can provide information about the construction of the device, identifying potential weaknesses or factors that should be improved.

This FP package houses a small semiconducting die, with wire attaching the die to the lead frame. Cross-section analysis, as a part of the constructional analysis, allows us to obtain information about the state of Die attaching, IC bonding, IC encapsulation and the whole internal structure.

Contact us

- Why Microsectioning sample preparation of PCB systems? - May 19, 2021

- Inspection of conformal coating on PCB using UV Light - August 4, 2020

- Plating Thickness Testing Overview in Alter Technology Lab. - July 28, 2020

0 comments on Constructional Analysis in Microsection Inspection