Tin Whisker Growth Investigation Conclusions

- Posted by Dimas Morilla

- On April 4, 2019

- 2

After the investigations we can prove Tin Whisker Growth Conclusions by Alter Technology, are divided into four thoughts:

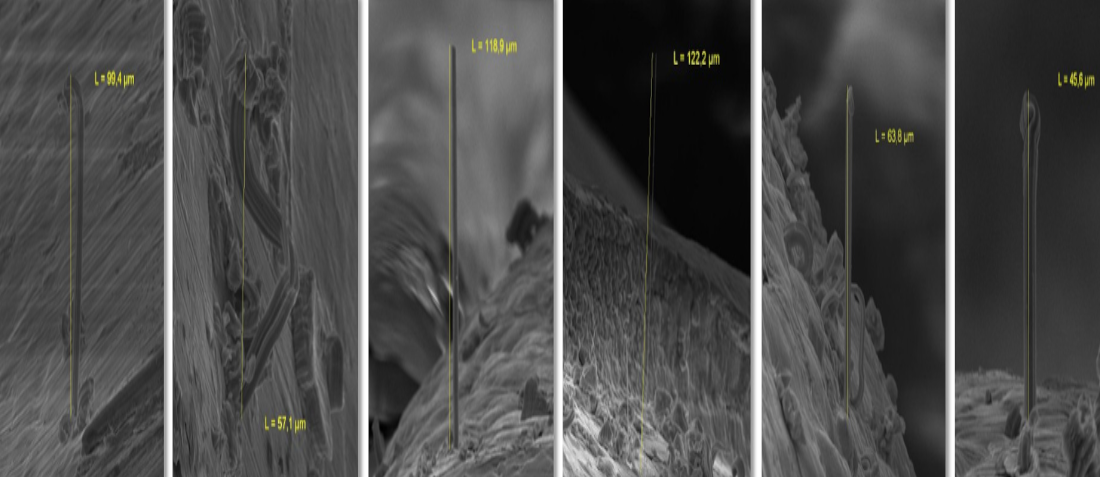

1.- This study corroborates that the Nickel (Ni) underlayer recommended by the industry as a diffusion protective barrier of the contact, is effective in delaying Stannum (Sn) whisker growth under ambient temperature/humidity storage conditions or during temperature cycling. But, it has also been found that this Nickel (Ni) based protection layer was not sufficient to stop the growth of whiskers after 12 weeks of storage at high temperature (55ºC) and high relative humidity (85%) conditions.

2.- The results presented here strongly suggest the importance of evaluating reliability through testing. A user of electronic components must be able to evaluate the whisker growth over their products life expectancy at field conditions to be confident in the effectiveness of the mitigation method employed.

| wdt_ID | Level | Description | Controls | System Types |

|---|---|---|---|---|

| 1 | I | No restrictions | None | Consumer Electronics |

| 4 | II | Use of Sn restricted only under pre-defined conditions | No general restrictions. Use may be banned in limited high-risk places | Commercial transportation Military test equipment |

| 7 | III | Use of Sn permitted under pre-set conditions | Blanket permission for classes of use, and on a case-by-case basis, if risk is minimal | Surface-based Radar and Communications Hi-Rel Commercial (Medical, Safety-critical) |

| 10 | IV | Use of Sn finishes as last resort | Permit use on a case-by-case basis, if no alternative, if risk is negligible | Avionics Missiles |

| 13 | V | Complete ban on pure Sn | No pure Sn, no exceptions | Space-based Implanted Medical Devices |

| Level | Description | Controls | System Types |

Table 5. Whisker Mitigation Levels

3.- The best strategy to prevent tin whisker induced failure of electronic hardware is to avoid using pure Sn plating on any of the parts.

It is important to be vigilant in the procurement of electronics components, particularly for space components, because once launched, they cannot be repaired and many spacecraft have intended lives of 14 years and some like Pioneer will continue communicating with Earth for more than 40 years.

4.- The accelerated acceptance tests recommended by the industry like the ones used here by JEDEC are not unique and they have not been compared with longer environmental exposures of components in service. It will be necessary to define specific standards for applications that demand high reliability.

After the conclusions in our company we are still working to have a better understanding of the phenomenon of tin whisker growth. This further work will improve to:

- Obtain a precise correlation between areas with a propensity to grow whiskers and those where few or no growths occur.

- It will be useful to study areas with and without mechanical damage and the effects of oxidation on the surface of tin plating, as this can occur during the kitting and assembly stages of electronic fabrication.

- In order to get closer to real operating conditions, it will be of great interest to perform future tests for studying the growth of whiskers under conditions of vacuum and in combination with electric current flow, both of which have been suggested as conditions that can accelerate the rate of growth of Sn whiskers.

- Würth Elektronik Presents Radio Interference Suppression Ceramic Common Mode Filter - December 24, 2021

- Results after the Tin Whisker Growth Investigations - December 4, 2020

- Why do a Residual Gas Analysis? - August 28, 2020

2 comments on Tin Whisker Growth Investigation Conclusions