A Quick Guide to Safety Capacitors

- Posted by doEEEt Media Group

- On September 7, 2022

- 0

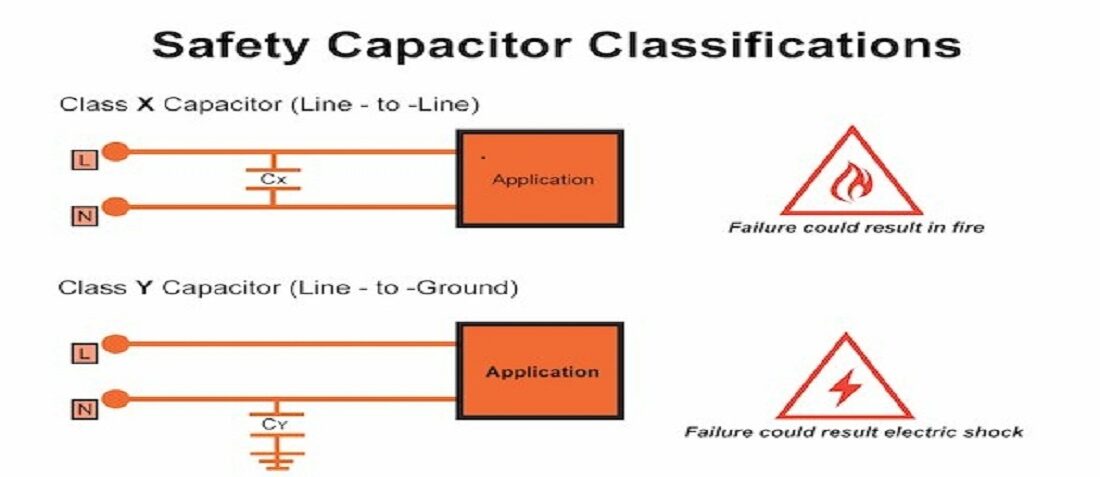

Certified Safety Capacitors are vital components for safety-critical across-the-line and line-to-chassis applications.

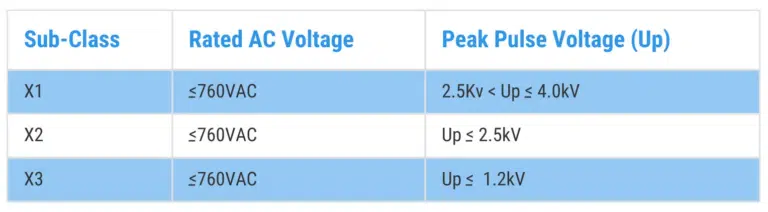

X-class capacitors are used across the line where failure would not lead to an electrical shock. X-class capacitors are divided into sub-classes by their rated and pulse voltage. See Table 1.

Table 1. X-class safety capacitors classification

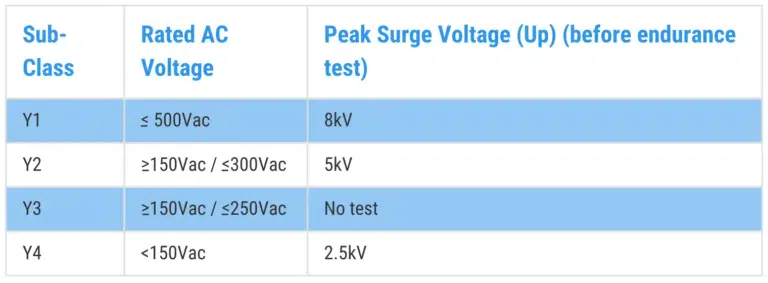

Y-class capacitors are used in “line-to-ground” applications where failure could lead to an electrical shock. It is also divided into sub-classes by their AC voltage and peak surge voltage ratings. See Table 2.

Table 2. Y-class safety capacitors classification

Safety X and Y capacitors are typically ceramic discs, multilayer ceramic, or plastic film capacitors in leaded or SMD packages.

Keeping up with classifications and certifications, knowing where they should go and which are interchangeable, can be very confusing for designers. In addition, there are multiple capacitor technologies to consider, all with varying lists of features and benefits.

Ceramic or Film capacitors, what fit better as X and Y safety capacitors

Some characteristics to consider would be the temperature profile over the application’s life, size constraints, and maybe even cost or ease of assembly. Ceramics can achieve higher capacitance values in a smaller volume, while the film has a self-healing feature inherent in the technology.

Ceramic safety caps are usually preferred for low-power applications due to their reduced size, but higher capacitance value safety caps are only found in film technology.

Most important design considerations and industry standards for safety capacitors

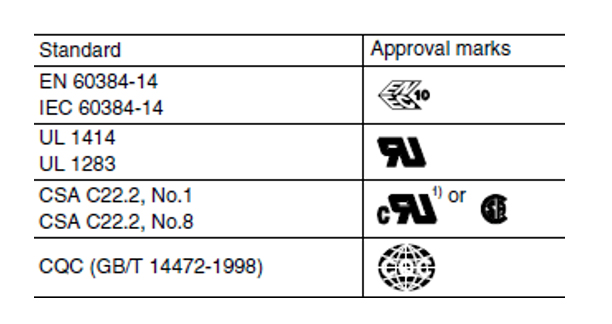

The industry follows several standards; the most common are:

However, the market for stringent applications has been defining requirements beyond the ones found by these standards. That is why it’s very important that designers understand the limitations of the components they are using.

The capacitor class and subclass are very important; they tell the designer what voltages and impulses the capacitor can withstand and which application it should be used for, i.e. across-the-line or line-to-ground. Certifications are also important to confirm IEC 60384-14.4 safety tests.

Safety capacitors in DC/DC converter applications

Safety capacitors can isolate the input and/or output if it is referenced back to a non-isolated buck on mains voltages, especially if a user has access to the connections or interface.

Standards require protection and safety devices for all equipment connected to the grid or subcircuits. These must be input filters and can operate as generic filters through the circuit.

Source: EPCI

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

- Filtering Characteristics of Parallel-Connected Fixed Capacitors in LCC-HVDC - November 21, 2024

- ALTER SPACE TEST CENTER: testing approaches for New Space - September 30, 2024

0 comments on A Quick Guide to Safety Capacitors